PE Sintering filter

PE sintered filter element using ultra-high molecular weight polyethylene sintering molding, compact structure, strong, light weight, can withstand higher filtration pressure, non-toxic and tasteless, acid and alkali solvent has good corrosion resistance.

PE sintered filter element using ultra-high molecular weight polyethylene sintering molding, compact structure, strong, light weight, can withstand higher filtration pressure, non-toxic and tasteless, acid and alkali solvent has good corrosion resistance.

PE sintered filter element by scientific formula of high temperature sintering, has good mechanical properties, and the filter element aperture inside and outside the same, easy to backwash slag.The filter layer is thick and the working pressure is high to ensure the filtering effect.Production of large water treatment equipment, can use automatic or manual recoiling slag method, solid particle recovery can be used dry slag, do not need to often replace the filter element, can be automated operation, low filtration cost advantages, by the user consistent good.

Advantage

1, PE filter aperture distribution is uniform, strong acid, strong alkali, high temperature resistance.

2. Good mechanical properties and strong corrosion resistance to organic solvents.

3. Before leaving the factory, each filter element shall be tested for bubble uniformity to ensure uniform distribution of micropores.

4, scientific formula firing, particles bond firmly, not easy to fall off.

Working condition | |

Design pressure | 0.7Mpa |

The highest heat resistance | 80°C |

Filter Precision | (Precision optional) |

Adapter interface | Thread type, flat mouth type, insert type, with end cover type, flange type |

Material | |

Filter material | PE |

Interface material | PP/ Polymer /20#(Iron)/PTFE/SS304/SS316 |

Tube material | PP/304/PTFE |

Seal ring | SILICOME /PTFE/ PFA/EPDM/NBR/Fluororubber |

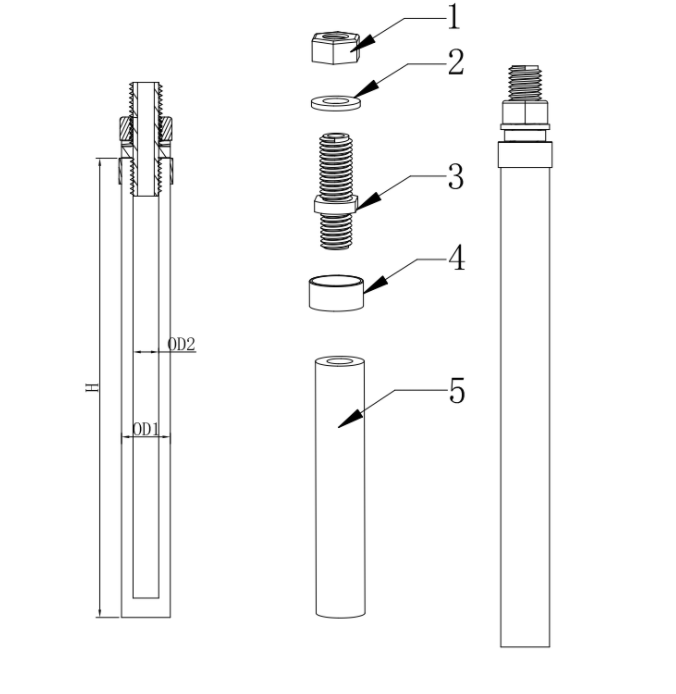

1 | Nut | Reinforced polypropylene/304/316L/PTFE |

2 | Gasket | PTFE、Silica gel, fluorine glue |

3 | Double-screw bolt | Reinforced polypropylene/304/316L/PTFE |

4 | Drivepipe | Reinforced polypropylene/304/316L/PTFE |

5 | Filter the ontology |

Core diameter(mm) | Filter inside(mm) | Filter length(mm) | Adapter interface | Interface material | Drivepipe | Gasket | Precision | |

MRFPE | 31 | 20 | 200 | M22*50 | PP | Empty | (Empty) | Precision |

31:31mm 38:38mm 40:40mm 45:45mm 50:50mm 63:63mm 78:78mm 100:100mm 120:120mm 150: 150mm (According to the actual mold size and inner diameter, please consult customer service for details) | 16:16mm 18:18mm 20:20mm 30:30mm 38:38mm 40:40mm 44:44mm 63:63mm 80:80mm 100:100mm 120:120mm (According to the actual mold size and the outside diameter, please consult the customer service for details) | 100mm-2000mm (The length is matched according to the actual mold size, please consult customer service for details) | M20*2.5*35 M22*3*50 M22*60 M24 M25 M3/4 DO: The two end D:Custom | PP:JPP 304:J304 316L:J316L Fe:J20# Macromolecules:JG PTFE:JPTFE (J):Other

| (Empty)Without the casing PP:TPP 304:T304 316L:T316L PTFE:TPTFE

| (Empty): silicone rubber silicone rubber:(S) PTFE:(PTFE) EPDM:(E) Nitrile butadiene:(N) Fluorelastomer:(F) Four fluorine coating:(PFA)

| 100: 100um 50: 50um 30: 30um 20: 20um 10: 10um 5 : 5um 3: 3um 1: 1um 0.5: 0.5um 0.2 :0.2um 0.1 :0.1um |