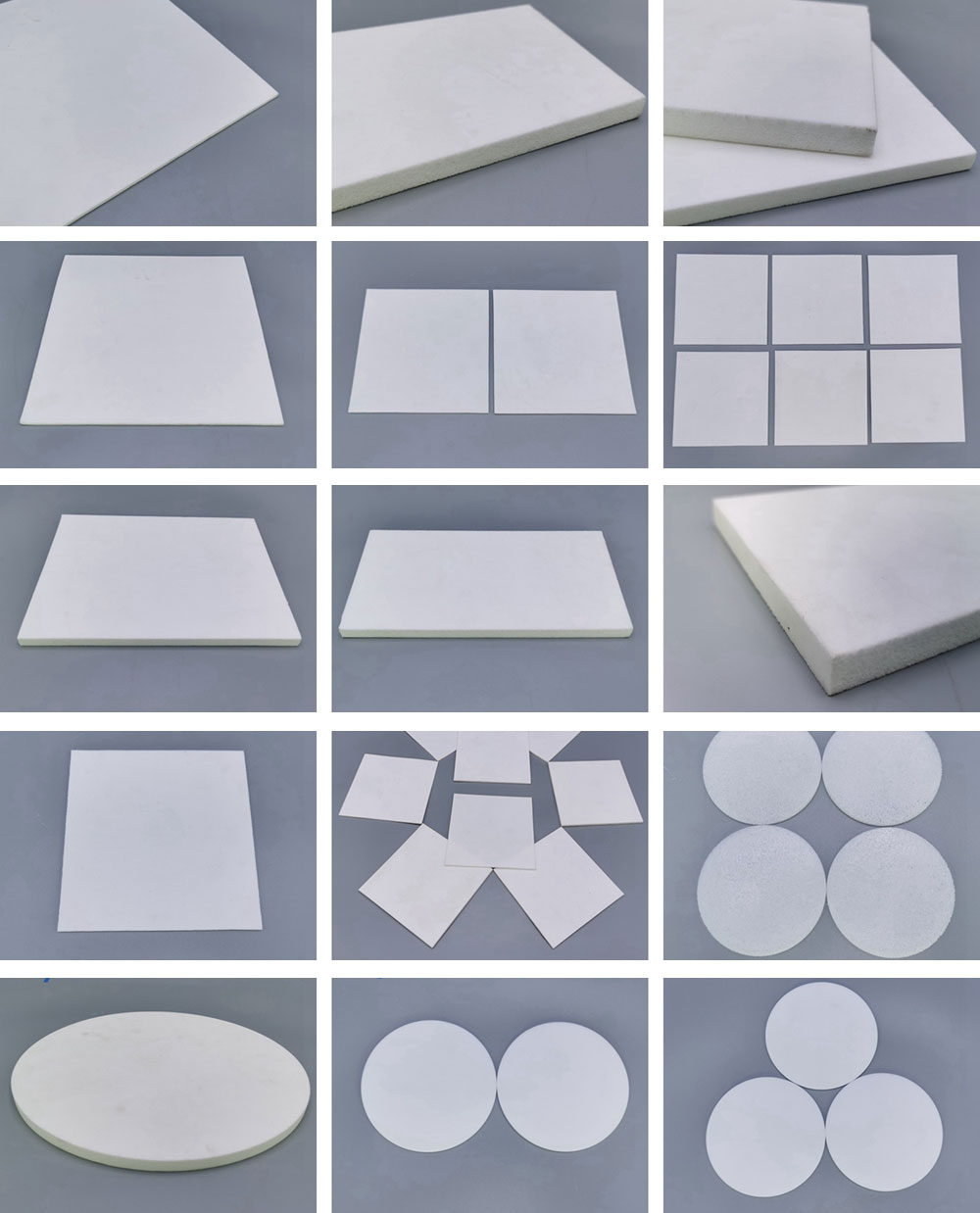

PE sintered vulcanized plate and support plate

Fluidization plate and filter plate are made of ultra-high molecular weight polyethylene (UHMWPE) as the main material or polytetrafluoroethylene (PTFE) material by high temperature and high pressure sintering into one, with circular and square shapes or other shapes.

Fluidization plate and filter plate are made of ultra-high molecular weight polyethylene (UHMWPE) as the main material or polytetrafluoroethylene (PTFE) material by high temperature and high pressure sintering into one, with circular and square shapes or other shapes. Can be customized according to customer requirements. Because of its fixed shape (free selection), uniform pore size, often used for powder operation as a gas distribution plate, the control of gas distribution state, powder material transmission and fluidization operation plays a decisive role, has a very wide range of applications in the industrial process; In liquid-solid separation (ion exchange column, chromatography column, etc.) as a support plate for dispersing porous solids.

In addition, the polymer composite material has the characteristics of antistatic pressure, so the filter plate is also widely used in electrostatic powder spraying, electrostatic generator barrel and fluidized bed device. PTFE coating is sprayed on the surface of the filter plate, which penetrates into the matrix of the polymer filter plate and forms ultrafine pore structure with it, so that the filter plate has good chemical stability, large filtration area, high porosity accuracy, uniform airflow distribution, small resistance loss and superior performance of flow gas distribution.

Our company can flexibly match and design the shape, pore size and permeability of the filter plate, so its comprehensive characteristics are excellent.

- PREV: Air and dust filter PE sintered filter element

- NEXT: Noise reduction PE sintered filter element