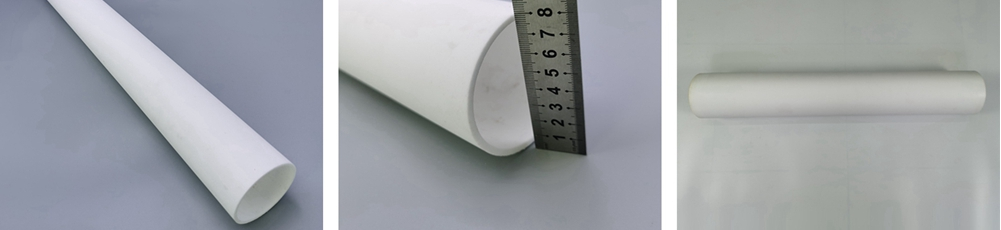

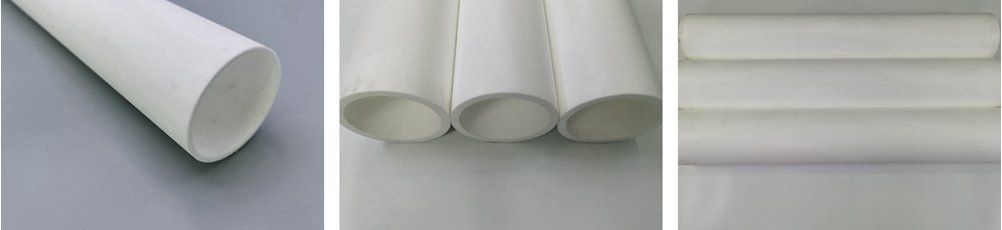

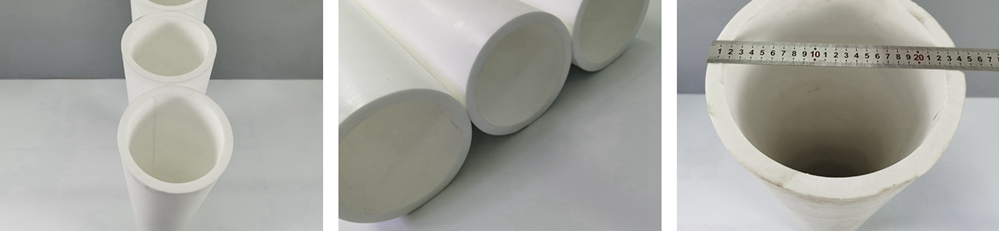

Polyethylene PE sintered filter tube

Using high quality ultra high molecular weight polyethylene as the main raw material, after scientific formula sintering molding, compact structure, strong, light weight, can withstand higher filtration pressure, and the aperture of the filter element is the same inside and outside, easy to reverse

Product performance:

PE sintered filter element has uniform pore size distribution and good circulation

Resistant to strong acid, alkali, salt and most organic solvents

Easy to blow back, high regeneration efficiency

Microporous PE material can withstand temperature 80℃, microporous PA material can withstand temperature 120℃

Non-toxic, tasteless, no media off, excellent mechanical properties, not easy to damage

The raw material conforms to THE requirements of GMP and FDA, without the use of adhesives, and has a wide range of chemical compatibility

Performance parameters:

1. Working temperature: PE≤80℃

2. Working pressure: 0.1Mpa-0.6mpa

3. Filtration accuracy: 0.2um-200um

PE sintered filter element application:

Application in environmental protection industry PE filter, such as heavy metals in electroplating industry CLP plating solution, heavy metal waste water salt purification filter, containing cadmium, copper, chromium, nickel, lead, plasma waste water treated with chemical method by PE microporous filter tube discharging standard, filter coal-bearing wastewater recycling, flue gas desulphurization filtering liquid water, dry dust collection, electrodialysis water purification filter;

Pharmaceutical, food industry PE filter application: such as pharmaceutical industry injection production injection liquid filtration and injection washing bottle water filtration, hydrogen peroxide production water purification filtration; Fermentation liquid filtration for antibiotic production, separation and filtration of sugar liquid and activated carbon for glucose production, crystal filtration for tetracycline production; Corn oil, soybean oil, rapeseed oil and other edible oil fine filtration;

Application of PE filter elements in petroleum, chemical and non-ferrous metal industries: precision filtration of liquid products, liquid raw materials and liquid intermediates: Such as all kinds of acid, alkali, salt and fine filtration of most organic solvents, acid and sulfur in chemical fiber production filter, brine in chlor-alkali industry production filter, activated carbon filtration in glyphosate production, metallurgy factory, film barium sulfate in the production of filter, can also be used as a plate and frame filter, after the centrifuge filtering precision. Nickel chloride, cobalt chloride, nickel oxalate, cobalt carbonate, nickel carbonate and other non-ferrous metal preparation process of acid leaching solution in addition to calcium and magnesium filtration, crystallization liquid filtration and washing.

Medical industry PE filter applications: liquid oxygen generator, pad, suction bottle, wet bottle, tide, oxygen tanks, blood collector check overflow, infusion the overflow, needle retention the overflow, and so on PE sintered filter has a very wide range of applications, oxygen generator sound attenuation filters, air intake air purification, oxygen tank secondary bacterial filter, oxygen generator out oxygen plus moist, and other functions. PE filter element clean appearance without powder off, cost-effective, is the ideal disposable oxygen treatment accessories, to ensure the oxygen humidification in the oxygen treatment process, improve the oxygen treatment effect, avoid cross infection, make oxygen treatment more safe and health.

PE sintered filter element cleaning method:

1. Physical method: because the filter rod has good mechanical properties and will not break, it can be backblown with 0.6mpa compressed air for slag removal and backblown at the same time

Play a capillary cleaning role, but after a long time of use in the accumulation of particles in the filter layer will affect the filtration speed, at this time to carry out chemical cleaning.

2, chemical method: the blocked PE, PA filter rod in the concentration of 5%-10% acid or alkali immersion, so that the blockage in the filter layer of micro material neutralization, and then water backwash or air backwash clean, filter filter effect can be restored.