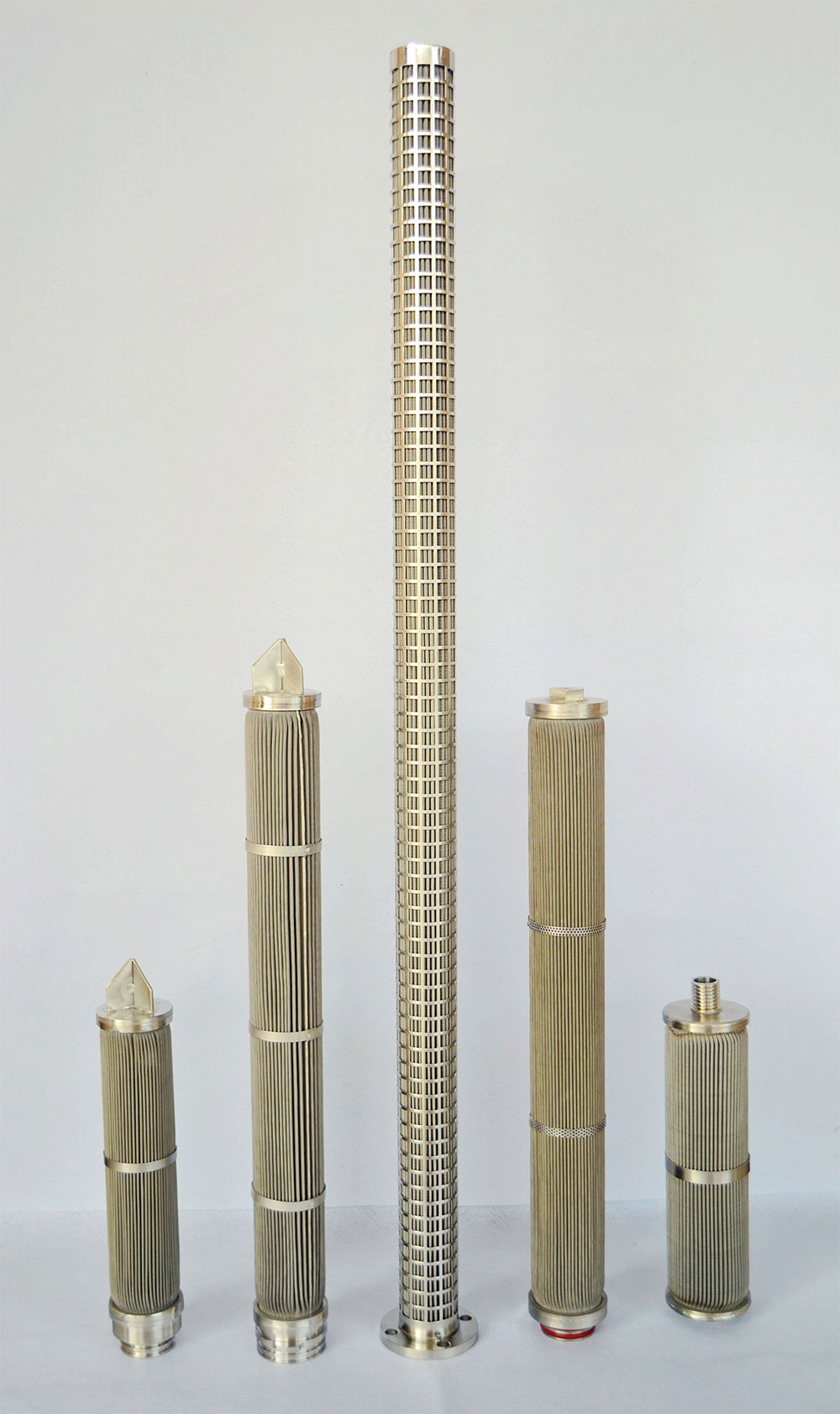

Stainless steel folding filter element

We are stainless steel filter manufacturers, the main stainless steel sintered mesh filter, folding filter, stainless steel filter, dust filter, stainless steel filter, filter cylinder and other filtering equipment, specifications and models are complete, the price is favorable.

Main material: 304, 316, 316L

Filter precision: 1~100um

Working pressure: 0~ 35MPa

Maximum operating temperature: 400 ℃

| Diameter (OD) mm | Length(L) mm | Precision(P) um | Interface type (I) |

| Φ65, Φ50, Φ38, Φ80, Φ110 | 250、500、1000 (Any length can be customized) | 1um、3um、5um、10un、20um、50um、100um | M20、M30、M36、222、 226、 D0 |

Stainless steel folding filter element is widely used in environmental protection, petroleum, chemical, medical, high temperature gas filtration, scientific research, metallurgy, food, machinery and other industries.His main filter material with 304, 304 l, 316, 316 l stainless steel fiber sintered felt and stainless steel net filter medium, filter the sealing surface with argon arc welding process, filter layer adopts multiple folding folding process, constitute a complete filter, no leakage, no medium falls off phenomenon, sintered stainless steel fiber felt is a kind of stainless steel fiber through high heat sintering porous depth filtration material form;Stainless steel woven mesh is made of stainless steel wire.

Product features:

1. Different from the stainless steel filter elements produced by other companies, the stainless steel folding filter elements produced by our company do not use adhesives in the production process, which has a wide range of chemical compatibility.Can be used for solvent or high temperature medium filtration.

2. After the rust steel precision filter element is folded, the filtering area is large and the pollution carrying capacity is large.Thus, the flow rate of a single filter element is large and the pressure difference is small, which is suitable for the working conditions with certain strict requirements on the pressure difference and the flow rate.

3, All stainless steel structure, the overall regeneration performance is good, after chemical cleaning, high temperature and ultrasonic cleaning can be used repeatedly.